rockwell hardness tester b scale|understanding rockwell hardness scale : mfg Most designers try to convert their hardness testing scales to more suitable ones like Rockwell hardness B and C scales. This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs. WEBEuro source on top of its monthly membership rate. A selection of Berlin gyms Urban strength. Large selection of weights. Closed on Sundays. Prices: 15.- Euro for a day pass or 49.- Euro per month. site: .

{plog:ftitle_list}

Resultado da 8 de dez. de 2023 · Grand Theft Auto: San Andreas: Advanced gaming on your Android. Grand Theft Auto San Andreas brings a console port of one of the most popular .

Most designers try to convert their hardness testing scales to more suitable ones like Rockwell hardness B and C scales. This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.You can choose a Rockwell hardness scale with suitable test forces (load) and .

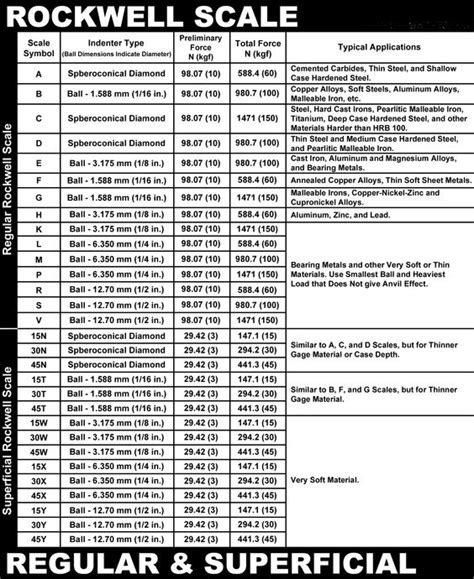

The Rockwell B-scale can be used in the case of softer materials such as brass, . Rockwell scale. The Rockwell scale is a hardness scale based on .Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 . Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables .

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers .

Hardness Conversion Chart - Rockwell "B" Hardness Range. Call us on (252) 344 - 2309. My Account.You can choose a Rockwell hardness scale with suitable test forces (load) and indenter size according to the material thickness that must be used in the procedure. The thickness can also be selected from the Rockwell scale table. .The Rockwell B-scale can be used in the case of softer materials such as brass, aluminum, and softer steel. It utilizes a hardened steel ball as an indenter along with a 100kg weight in order to derive a value, which is expressed as ‘HRB’.

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from .

The Rockwell hardness B scale used for soft or mild metal materials, is the second most common hardness scale in the testing field. The information provided in this article is likely to be enough for you if you want to proceed with this test for hardness deduction purposes.

Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic Scales. There’s also Rockwell Hardness Scales used for polymers and plastics. These are .Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Find the hardness conversion for Rockwell B scale or high hardness range here. Download as PDF or get the Rockwell conversions right away.

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool forRockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.

understanding rockwell hardness scale

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.Rockwell scales allow you to follow the standard scale tables and rules to get the accurate values of the hardness of your test material. + 86 755 61301520 [email protected] The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .What is the Rockwell Scale? Rockwell hardness testing is the most commonly used hardness testing method to measure the permanent depth of an indentation, which is finally compared to the Rockwell scale to derive the hardness number. . while low hardness range involves Rockwell B Scale. The below mentioned chart will highlight the hardness .

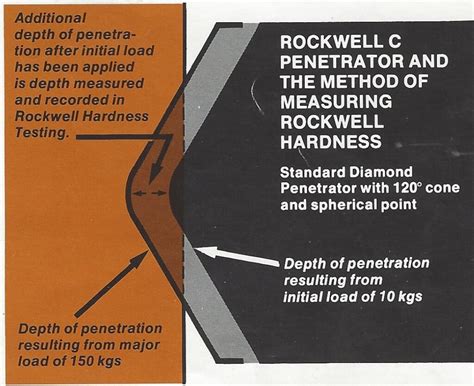

Rockwell Hardness Testers – Bench Analog Models Analog Rockwell Hardness Tester Phase II - Model 900-331 Rockwell Superficial Hardness Tester Phase II - Model 900-345 Rockwell/Superficial Twin Hardness Tester Phase II - Model 900-375 Rockwell Hardness Testers – Bench Digital Models Tru-Blue II Digital Rockwell and SupeScale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .In conversion scales, common terms which should be first understood are scales, symbol, indenter and load or test force. All of these tables are based on these terms. For any hardness test, these tables are used for conversion of .

ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Test Scales Rockwell and Rockwell Superficial Rockwell Rockwell and Rockwell Superficial Standard JIS B 7726 ISO 6508-2 ASTM E18-10 Preliminary Test Force 98.07N (10kgf), 29.42 (3kgf) 98.07N (10kgf) .The Wilson Rockwell 574 Hardness Tester Series stands out for its quality, durability, and leading Gauge Repeatability and Reproducibility (GR&R) in hardness testing instruments. Offering regular scale or twin (regular and superficial scale) models, these testers conform to ASTM E18 and ISO 6508 standards, catering to various needs.Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.

large area burst polarimeter

The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell scale is .How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog If the hardness exceeds this range, use Rockwell hardness A scale (HRA). If the hardness is below this range, use Rockwell hardness B scale (HRB). The upper limit of Brinell hardness is HB650; it cannot exceed this value. 4. The indenter for the Rockwell hardness tester C scale is a diamond cone with a 120-degree apex angle.

Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in difficult testing situations. . HRA Scale - Carbide Test Diamond Indenter - Newage Indentron and Indentec Testers: 205: HRC,HRA,HRD & HRN Scales Diamond Indenter .The clamping ability is an inherent part of this Rockwell hardness tester and provides the user with the ability to clamp and hold parts in place prior to testing with up to 240 foot pounds (325 Nm). By clamping instead of using jack screws or cutting specimens, the test accuracy is improved and the testing time is decreased.the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may be narrower than those indicated. 2 REFERENCE The following Indian Standard contains provisions which through reference in this text, constitutesRockwell hardness test according to the material hardness, thickness of the test, can choose A different head and test, and the different scale, says the most common have A, B, C scale, in the . B Scale:Used for testing of non‐ferrous metals and .

There are several alternative scales, the most commonly used being the "B", and "C" scales. Both express hardness as an arbitrary dimensionless number. The B-scale is used for softer materials (such as aluminum, brass, and softer steels). It employs a hardened steel ball as the indenter and a 100kg weight to obtain a value expressed as "HRB".

laurent half shade polarimeter

Resultado da O Itaú Empresas na internet é um canal de atendimento seguro e protegido por criptografia com chave de segurança, mas para manter sua conta ainda mais segura é sempre bom: evitar usar computadores de terceiros e conferir seus dados antes de digitar sua senha eletrônica. Acesse para saber mais .

rockwell hardness tester b scale|understanding rockwell hardness scale